Advanced Manufacturing

Advanced manufacturing for aerospace, wind, solar, semiconductor, and other cleanroom-based production demands more than a “typical” industrial building. We design structural and civil systems that control vibration, support heavy and dynamic equipment loads, and accommodate dense overhead utilities, pipe racks, and mezzanines while also addressing grading, drainage, utility corridors, and heavy-duty pavements to keep sites efficient, expandable, and operational.

Get In Touch

- 303.431.6100

- info@martinmartin.com

Because of the sensitive nature of these projects, we are often unable to share project imagery. We respect our clients’ confidentiality requirements and associated NDAs. Below are several key considerations we routinely address in the design of these specialized facilities.

Sensitive Compartmented Information Facilities (SCIF) Construction

We support secure environments across a wide range of security levels, including projects aligned with ICD 705 with tempest requirements. Our civil and structural teams understand the rigor of secure spaces, whether within existing facilities or new construction, and coordinate closely to support compliance, constructability, and schedule.

Equipment Support & Tank Farms

Advanced manufacturing equipment drives design decisions. We provide integrated civil and structural support for equipment foundations, housekeeping pads, pits, trenches, anchorage, and overhead supports, coordinating with original equipment manufacturer (OEM) criteria, installation sequencing, and utilities to enable smooth procurement, installation, and commissioning.

Facility Maintenance and Upgrades

Facilities don’t pause for improvements. We help owners plan and execute repairs, maintenance, and phased upgrades with practical solutions that work around live operations, supporting everything from slab and pavement repairs to structural modifications and constructible detailing for efficient field execution.

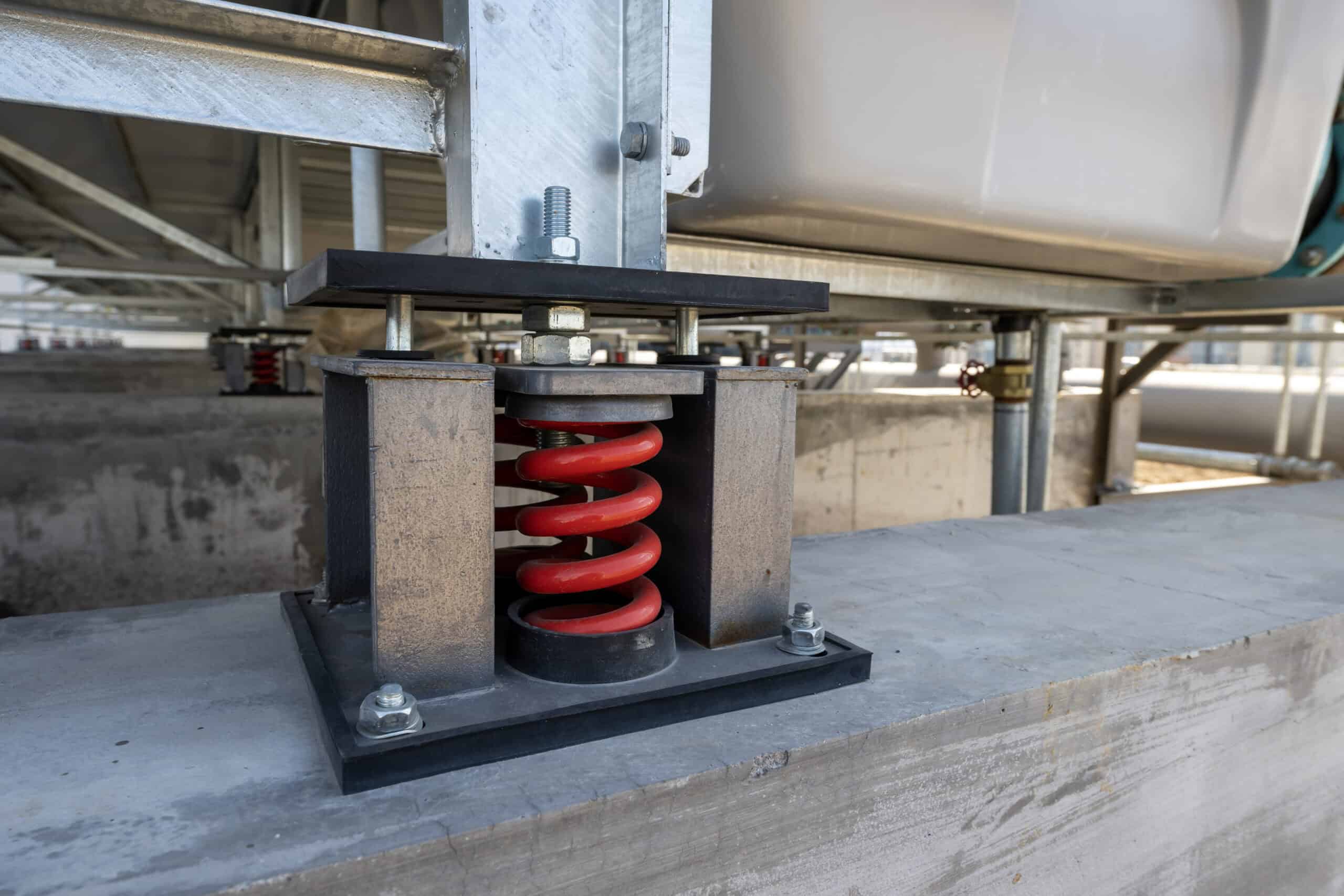

Vibration Performance

Precision manufacturing depends on predictable vibration performance. We evaluate vibration criteria and sources (equipment, foot traffic, adjacent operations) and design targeted structural solutions, including stiffening, isolation strategies, and reinforcement, to support sensitive processes and long-term reliability.

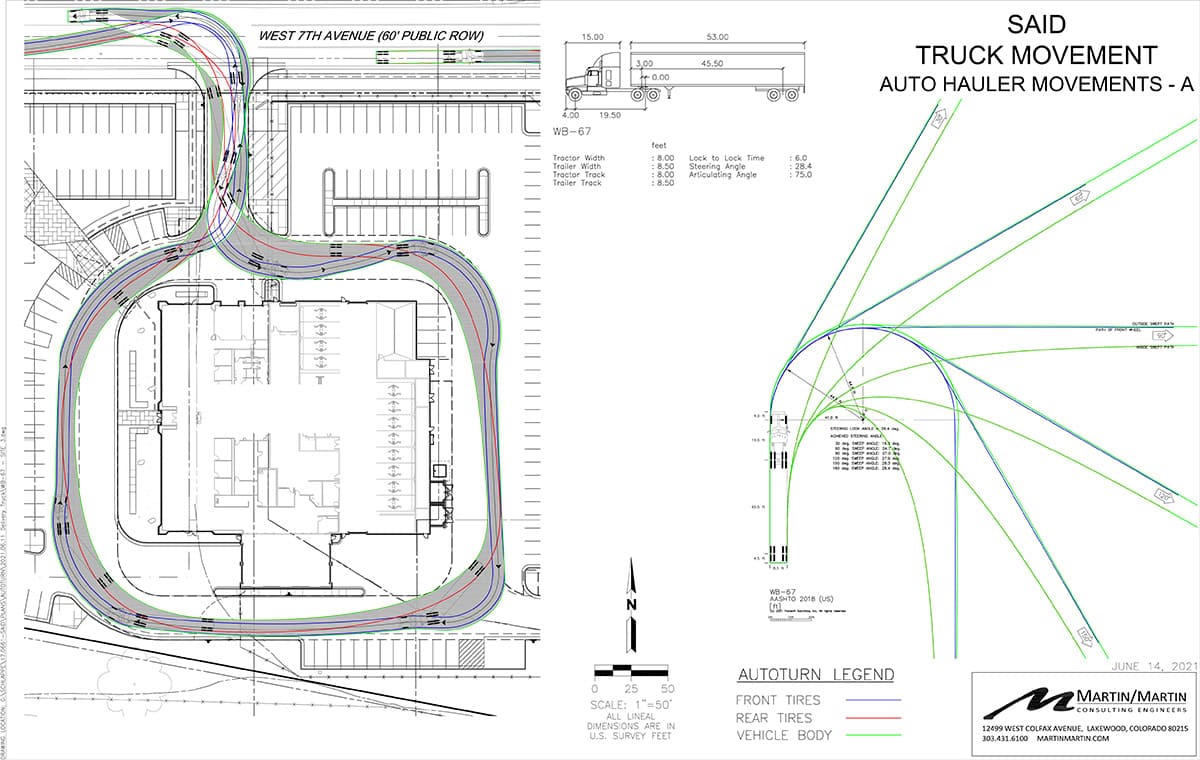

Heavy Truck and Logistics Movement

Site logistics can be as demanding as the building itself. Our civil and structural teams design pavements, slabs, foundations, and loading areas for heavy truck traffic, repeated wheel loads, turning movements, and impacts supporting durable performance at docks, yards, and critical circulation routes.

Risk and Loss-Prevention Alignment

Mechanical Coordination

Mechanical systems are often the biggest driver of space, routing, and structural impacts in advanced manufacturing facilities. We coordinate closely with mechanical teams to plan clearances, equipment placement, penetrations, support and hanger strategies, rooftop and mezzanine loads, and access for maintenance and replacement, helping reduce clashes and late changes in the field. This collaboration extends beyond the building to site and utility needs, aligning foundations, pads, trenches, and drainage considerations with mechanical yard layouts and process requirements to keep installation and commissioning on track.